Braden Moore once envisioned being a fighter pilot when he was a young boy, perhaps inspired by Tom Cruise's character Pete “Maverick” Mitchell in Top Gun, which was released in May 1986 just before Moore turned two.

And while he ended up gravitating to construction and joining his father, Rob, and brother, Cory, at Salt Lake-based Big-D Construction, he did consider other career options, at least initially.

While in high school, Moore eschewed working at Big-D once he turned 16 and instead spent his junior and senior summers building log homes with a cousin and some high school buddies in Colorado. In addition to paying well—the impetus behind it all—Moore found great satisfaction in the building process, especially the finished product.

"That's where I started getting a passion for construction, a passion for seeing what you built," said Moore, 40, who currently serves as Vice President of Big-D's Salt Lake office. "I really love seeing what a team did together and seeing the result of hard work.

After graduating high school, Moore served a mission to Romania from 2003-2005, a time he called challenging, yet rewarding. He immediately went to work full-time for Big-D in 2005 during summers while earning a Bachelor of Business Administration from Utah State University from 2006-2010.

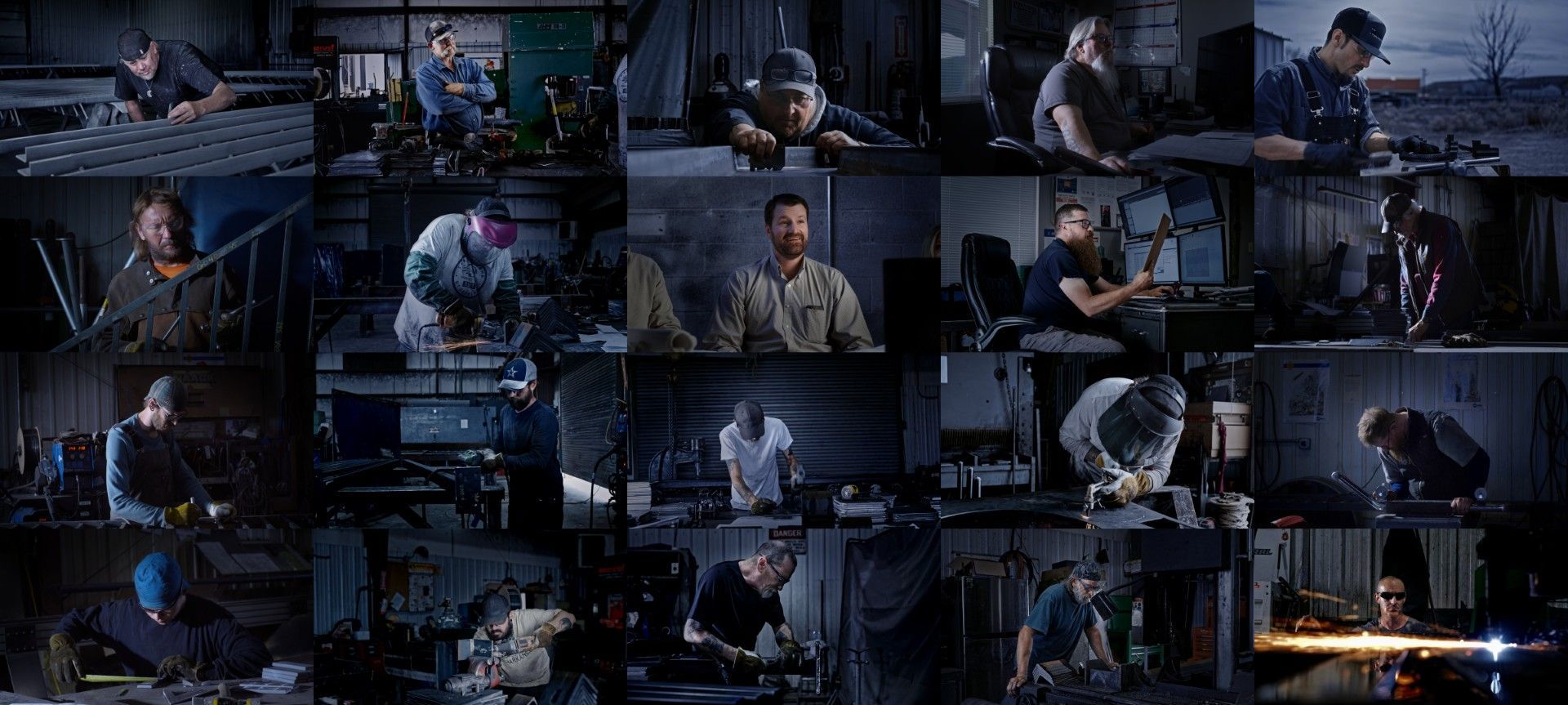

Initially, Moore was in the field for more than two years, doing concrete work, carpentry, and anything that needed to be done on a job site. It taught him the roots of the trade, learning from seasoned veterans like Brett Allen and Lynn Turner, two of Big-D's most skilled field workers.

"I just loved learning the business from guys who have been at it for the longest time," said Moore. "It taught me the business, about what it means to work your butt off for 40-50 hours a week. There is a lot of responsibility that comes with that, values that are bred through hard work. I learned a lot about life."

Rob, who serves as Executive Chairman after nearly 25 years as Big-D's President/CEO and nearly a half-century at the company, explicitly instructed Braden's bosses to show him the ropes.

"I told them, 'I want you to work him harder than anyone else, show him no favors'," Rob said. "LT (Turner) taught him to be productive [...] we're not going home until it's done, that's the mentality. There were no gifts. It was about learning the process of building from the ground up."

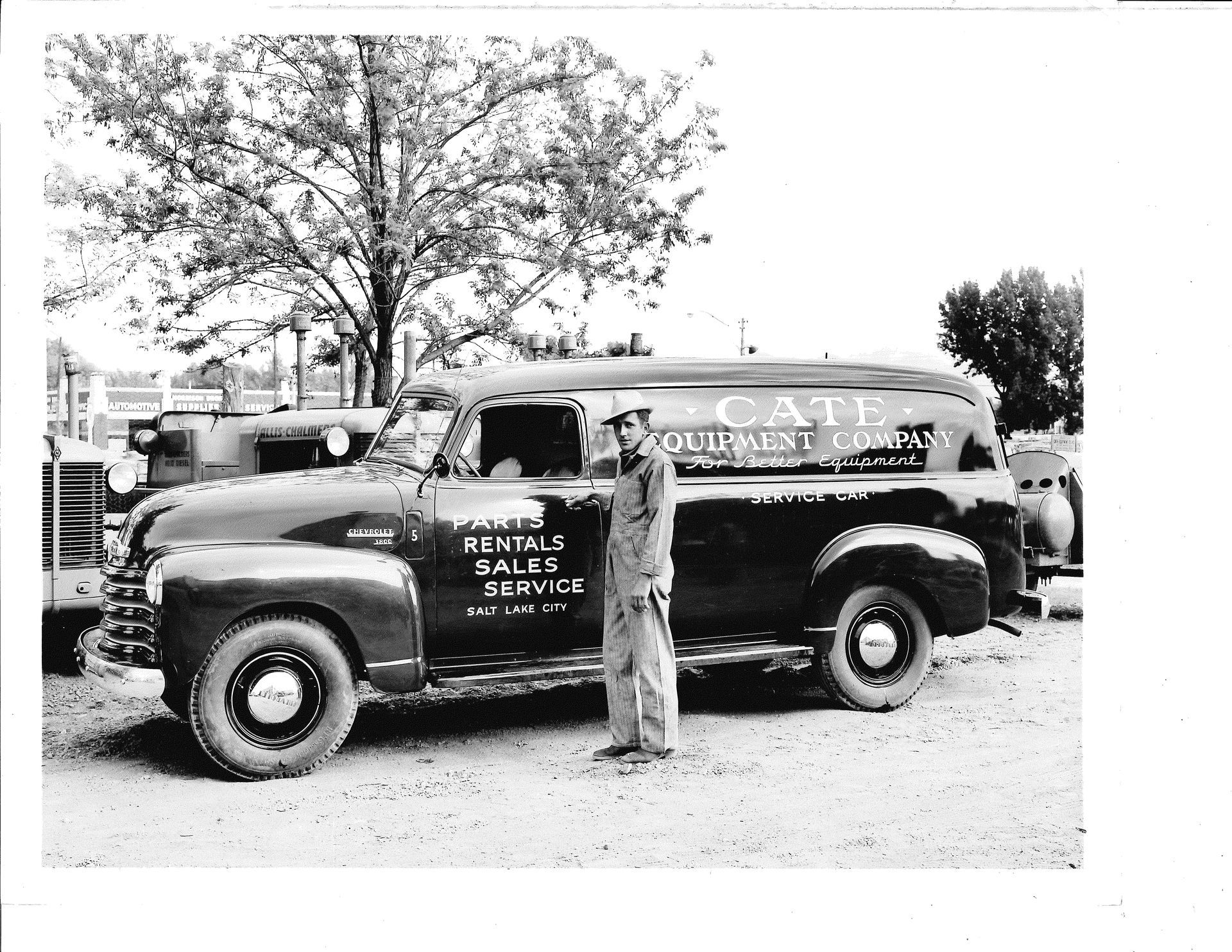

The elder Moore grew up on a ranch and worked for his father's small excavation company. In an interview with UC+D in early 2016, Rob said he quickly learned "there are no free things in life. I grew up in an environment where you earn your way every day. A lot of folks who come from a rural environment from my generation, we grew up working hard."

Rob said having Cory and Braden work in the field before transitioning to the office was crucial to their overall training and understanding of the industry.

"It was important for my boys to not be on a silver spoon program—that's 100% against my personality," Rob emphasized. "They have to work hard and earn their way, or they don't have respect from anybody. You've got to have that base and then take it to the next level."

He continued: "Everything we do is process—you've got to understand the sequencing. If you understand how to put a project together in the field, you know how to do it in the office. Braden got to see all that."

In 2008, Moore transitioned to the office in a business development capacity, something he had little familiarity with, but a role he tackled head-on as he worked closely with Forrest McNabb, Big-D’s National Food & Beverage President.

In 2010, Moore started working with Rich Hazel on smaller commercial projects, a strategy Rob said is designed to take care of literally anything a client—particularly existing ones—might need, no matter how large or small it might be (under $10 million).

"It was a way to better take care of repeat customers," said Rob. "We don't want our customers calling someone else to take care of them. It was a way to get over the misnomer that we don't do small jobs. Big-D is about relationships—that's what [Big-D founder] Dee [Livingood] started. Make a promise and see it through."

"We'd find a project and Rich would coach me on the art of negotiation, coach me on different contract types," said Moore, adding that he'd get involved in all aspects including estimating and project management. "It was huge for [helping] me understand all aspects of the business."

"I love his honesty and energy," said Hazel, a 14-year veteran of Big-D who was named President of the Salt Lake office in 2022. "He thinks strategically. Those attributes resonate with people. Braden's relationships in the community are second to none."

Moore also spent time as National Business Development Director, which gave him a chance to interact with all of Big-D's offices—now numbering 17 different business units in 19 offices (four offices in Utah, including Ogden, Salt Lake, Lindon, and Big-D Signature in Park City).

He was named Vice President of Salt Lake at the same time Hazel was named President, and the two share a similar passion for the industry, creating a unique synergy that has the office firing on all cylinders and generating about one-third of Big-D's $3 billion annual revenues.

Moore recently landed an $800 million project in Utah–a mammoth-sized job that represents one of the single largest projects in Big-D's 57-year history.

"Braden has played a pivotal role in some of our largest and most significant projects," said Cory, Big-D's CEO. "He is a master of relationships, consistently fostering customer loyalty and trust through his genuine approach and commitment to excellence. His leadership skills are exemplary, guiding our teams to achieve remarkable results while creating an environment where collaboration and innovation thrive. Braden's wealth of knowledge, coupled with his larger-than-life personality, has made him a cornerstone of our success."

Moore may not have become a fighter pilot, but he's no doubt soaring to great heights in the construction industry.